For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Ceramic waste grinding is a crucial step towards enhancing sustainability and promoting resource efficiency in various industries.

By reducing ceramic waste to smaller particles or powders, its recyclability, reusability, and suitability for diverse applications are significantly enhanced.

Through the utilization of suitable grinding mills, such as ball mills, hammer mills, and vertical roller mills, ceramic waste can be processed efficiently and effectively, contributing to a more sustainable future and mitigating environmental impacts associated with ceramic production and waste disposal.

Ceramic waste encompasses a broad range of materials, including offcuts, rejects, broken tiles, pottery, and obsolete ceramic products.

Characterized by their durability, heat resistance, and aesthetic appeal, ceramics find applications in numerous industries, ranging from construction to electronics.

Despite their desirable properties, ceramics pose challenges in terms of waste management due to their low biodegradability and resistance to natural decomposition processes.

As a result, ceramic waste often accumulates in landfills, contributing to environmental pollution and resource depletion.

The necessity of grinding ceramic waste arises from its inherent characteristics and the need to mitigate environmental impacts while unlocking its potential for reuse and recycling. Several key factors underscore the importance of ceramic waste grinding:

Ceramic waste typically exists in the form of large pieces or chunks, making it unsuitable for direct reuse or recycling. By grinding ceramic waste into smaller particles or powders, its surface area increases, facilitating subsequent processing and incorporation into new materials.

Grinding ceramic waste enhances its recyclability and reusability in various applications. Finely ground ceramic waste can be incorporated into new ceramic formulations, construction materials, or industrial products, reducing the reliance on virgin raw materials and promoting circular economy principles.

Through ceramic waste grinding, the demand for natural resources in ceramic production and construction can be minimized. By utilizing recycled ceramic materials, the depletion of finite resources, such as clay and sand, can be mitigated, contributing to sustainable resource management.

Grinding ceramic waste reduces its volume, facilitating efficient waste management and disposal. Smaller particle sizes enable denser packing and storage of ceramic waste, thereby minimizing the space required for landfilling and reducing transportation costs.

By diverting ceramic waste from landfills and incorporating it into value-added products, the environmental footprint associated with ceramic production and waste disposal can be reduced. Ceramic waste grinding plays a crucial role in mitigating greenhouse gas emissions, conserving energy, and preserving natural ecosystems.

To effectively process ceramic waste and achieve the desired particle size reduction, various types of grinding mills are available, each with unique features and capabilities. The selection of a suitable grinding mill depends on factors such as the desired particle size, throughput requirements, and the specific characteristics of the ceramic waste being processed. Here, we introduce several grinding mills commonly used for ceramic waste processing:

Raymond mill, also known as Raymond roller mill, is a widely used grinding mill in various industries, including mining, construction, and chemical engineering. It operates on the principle of grinding materials between rollers and grinding rings. Ceramic waste is fed into the grinding chamber, where it is crushed and ground by the rollers rotating around the central shaft. The ground material is then blown by the airflow generated by a fan and collected in a cyclone separator or bag filter.

Raymond mill offers several advantages for processing ceramic waste:

l High Efficiency: Raymond mill has high grinding efficiency and can produce fine ceramic waste powder with relatively low energy consumption.

l Versatility: It can grind a wide range of materials, including ceramics, minerals, and ores, making it suitable for various applications.

l Particle Size Control: Raymond mill offers precise control over particle size distribution, allowing for the production of ceramic waste powder with specific particle sizes.

Ultra-fine grinding mills are designed to produce ultra-fine powders with particle sizes in the submicron range.

Ultra-fine vertical roller mill combines the advantages of vertical roller mill and ultra-fine grinding mill. It features a vertically oriented grinding disc and a classifier wheel for precise particle size control. Ceramic waste is fed into the grinding chamber, where it is pulverized by the grinding rollers and classifier wheel. The ultra-fine powder is then separated from the air stream and collected in a cyclone separator or bag filter.

Ultra-fine grinding mills offer several advantages for processing ceramic waste:

l Extreme Fineness: Ultra-fine grinding mills can produce ceramic waste powder with ultra-fine particle sizes, making them suitable for high-value applications such as advanced ceramics and electronics.

l High Purity: These mills can produce ceramic waste powder with high purity and uniform particle size distribution, meeting the stringent requirements of various industries.

l Energy Efficiency: Ultra-fine grinding mills are designed for high-efficiency grinding, minimizing energy consumption and operating costs.

Ball mills are versatile cylindrical devices equipped with grinding media, such as ceramic balls, and operate by rotating the chamber around a horizontal axis. Ceramic waste is fed into the mill, where the grinding media crush and grind it into fine particles. Ball mills are suitable for both wet and dry grinding and offer high throughput rates, making them ideal for processing ceramic waste in large quantities.

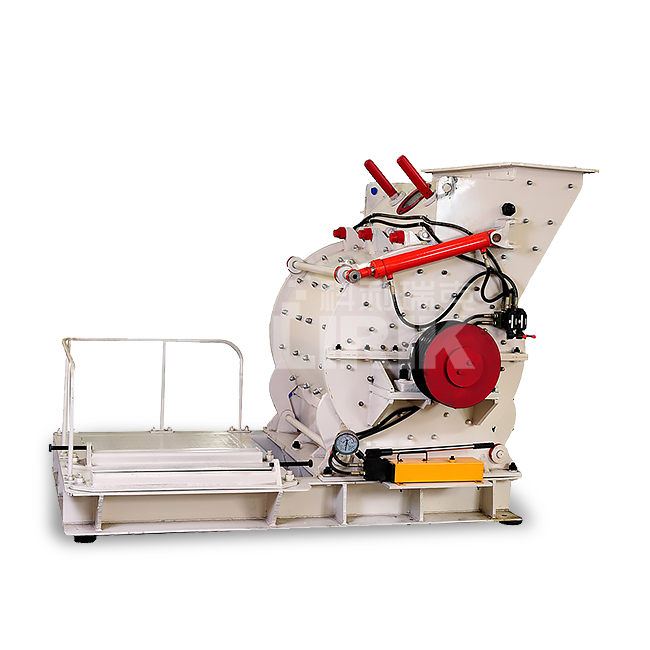

Hammer mills consist of rotating hammers mounted on a central shaft within a cylindrical chamber. Ceramic waste is fed into the mill and subjected to impact from the rotating hammers, resulting in size reduction. Hammer mills are effective for grinding brittle materials and offer flexibility in achieving different particle sizes.

Vertical roller mills feature a rotating table or disc equipped with vertically oriented rollers that crush and grind ceramic waste against a stationary grinding table. Vertical roller mills are known for their energy efficiency and ability to produce finely ground materials with narrow particle size distributions. They are suitable for both dry and wet grinding applications.