For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Crushing and grinding are essential steps in the processing of copper ore. They prepare the ore for further concentration and extraction of copper. CLIRIK offers several crushers and grinding mills suitable for copper ore processing

Purpose: To reduce the size of the ore from its natural size to a more manageable size.

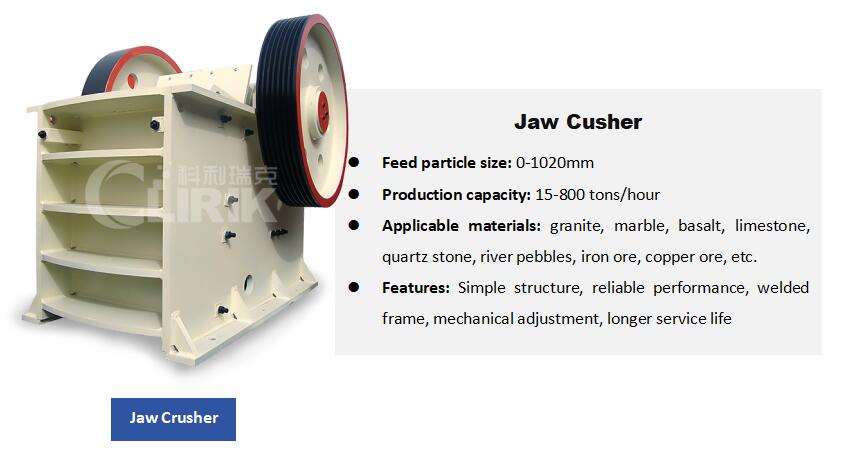

Equipment: Jaw crushers, gyratory crushers.

Process: The ore is fed into a primary crusher, which breaks it down into smaller pieces, typically from 30 to 150 mm in size.

Use: For primary crushing of large ore pieces.

Features: Efficient at breaking down large rocks into smaller, more manageable sizes.

Purpose: To further reduce the ore size to achieve the desired feed size for grinding.

Equipment: Cone crushers, impact crushers.

Process: The ore from the primary crusher is fed into secondary crushers, which further reduce the size to 10-50 mm. Tertiary crushers may be used for even finer crushing if necessary.

Use: For secondary and tertiary crushing, providing finer ore particles.

Features: Ideal for shaping and reducing ore size with high efficiency.

Use: For secondary and tertiary crushing stages.

Features: Provides a finer output and is suitable for hard ores like copper.

Objectives of Crushing and Grinding

Liberation: To liberate the copper minerals from the waste rock so that they can be concentrated and extracted.

Size Reduction: To reduce the ore to a size suitable for the concentration process.

Efficiency: To ensure that the subsequent stages of the processing plant, such as flotation, can operate effectively.

Properly crushing and grinding the ore is critical for maximizing recovery and ensuring the efficiency of the downstream processes.

Purpose: To achieve fine grinding of the ore to liberate copper minerals.

Process: The crushed ore is mixed with water in a ball mill where steel balls grind the ore to a finer size, typically to 100-200 mesh. This process is often done in stages, with initial coarse grinding followed by finer grinding.

Use: For ultra-fine grinding applications.

Features: Produces very fine copper ore powder, useful for high-purity processing needs.

Use: For medium to fine grinding.

Features: Versatile and efficient for producing copper concentrate and intermediate products.

Use: For fine and super-fine grinding.

Features: Offers high grinding efficiency and precision.

These equipment options from CLIRIK are designed to handle different stages of copper ore processing, ensuring efficient and effective production.

Use: For coarse to medium grinding.

Features: Energy-efficient and compact, suitable for large-scale processing.

As a leading mining equipment manufacturer, CLIRIK Machinery provides you with professional crushing and grinding solutions. For more details about copper ore crusher and grinding mill, welcome to contact us for more details.

Email: sales@clirik.com

WhatsApp: +8613512155195