For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

The CLQM Series Air Classifying Mill is a popular choice for grinding a wide range of materials, including dry fine chemicals and food products. This versatile machine combines the power of a mechanical impact mill with a dynamic air classifier, making it ideal for continuous processing of medium to small volumes.

The CLQM Series Air Classifying Mill is a popular choice for grinding a wide range of materials, including dry fine chemicals and food products.

This versatile machine combines the power of a mechanical impact mill with a dynamic air classifier, making it ideal for continuous processing of medium to small volumes.

With years of experience behind it, the mill can be tailored to suit different materials.

You can also customize it with various grinding tracks and impact elements to meet the specific needs of your product and desired outcome.

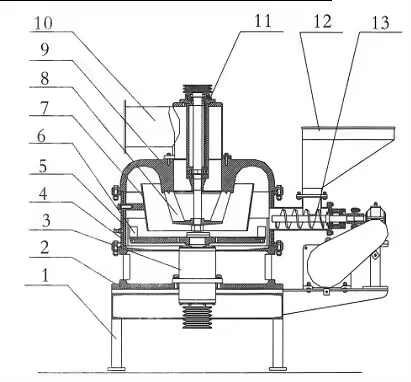

The CLQM series air classifying mill is made up of several key components that work together to ensure efficient grinding. These include the screw feeder, grinding unit, classifier, power section, cyclone, filter, blower, and electrical panel. The main components also feature the motor, mill disc, mill blocks, classifier, inlet liner, main shaft, and mill baffle.

Here is a breakdown of the main unit components:

1. Base

2. Lower body

3. Main bearing assembly

4. Middle body

5. Fixed blocks

6. Mill disc

7. Airflow baffle

8. Classifier impeller

9. Upper cover

10. Outlet hole

11. Classifier bearing assembly

12. Hopper

13. Feeding part

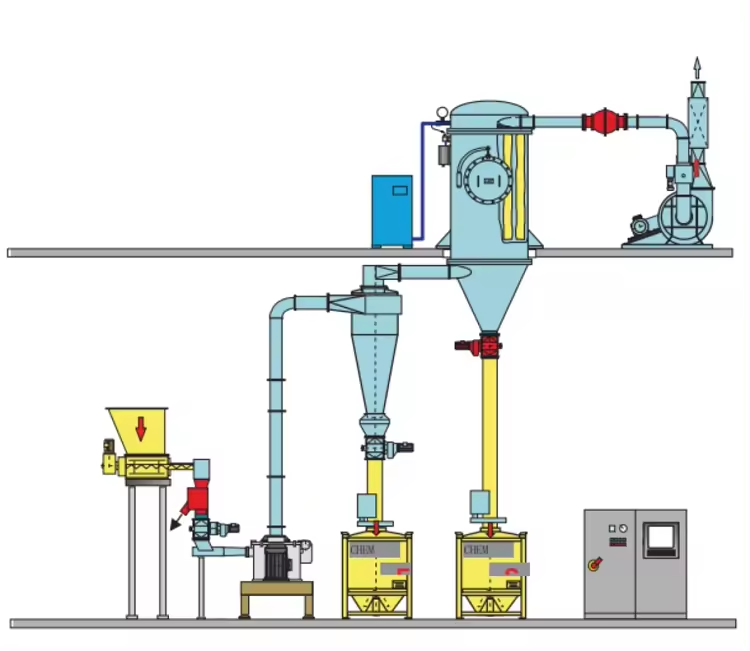

The process begins when material is fed into the grinding chamber by the feeding system.

Once inside, the material is hit by the high-speed rotating grinding disc, which applies a strong impact.

At the same time, centrifugal force pushes the material against the grinding ring gear, where it undergoes various forces, such as shearing, friction, and collision, until it’s finely ground.

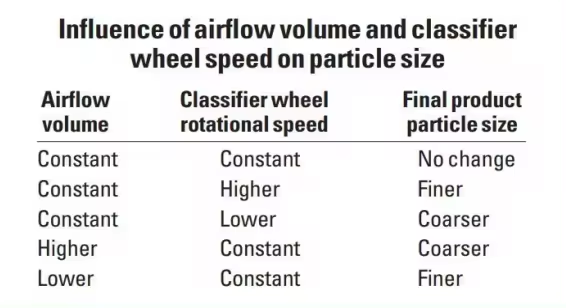

The ground material then moves into the classifying zone along with the airflow.

Here, the classifier—adjusted by frequency conversion—separates the fine material from the coarse.

The fine particles that meet the desired fineness are carried by the airflow into the cyclone collector and dust collector, while the coarse particles are sent back for further grinding.

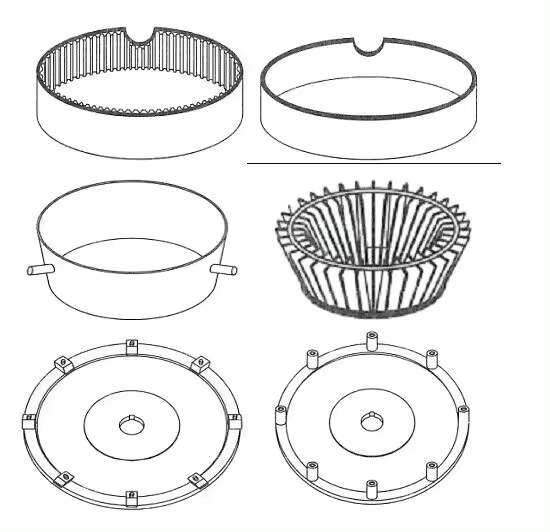

1. Multi-functional Design: This mill combines cooling, drying, grinding, and classifying all in one machine, offering versatile processing options.

2. Customizable Grinding: Depending on the material's characteristics, you can choose different types of grinding discs—like pin, hammer, or teeth—to achieve the best grinding force and efficiency.

3. High Purity Output: The key components, such as the hammer, gear ring, and classifying wheel, are made from ceramics like aluminum oxide, zirconium oxide, or silicon carbide. This ensures no contact with metal, keeping the final product extremely pure.

4. Space-Saving and Easy Maintenance: The mill's compact design takes up little space, and it's easy to disassemble and clean, making maintenance a breeze.

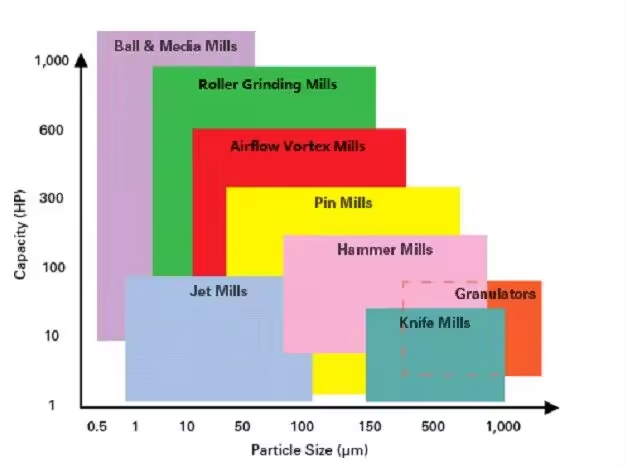

Please note: The Airflow Vortex Mill in the red part of the picture refers to the Air Classifying Mill

With over 1,000 installations worldwide, the CLQM series air classifying mill is trusted across a variety of industries:

l Chemicals: Ideal for processing materials like bisphenol, tartaric acid, E-PVC, fungicides, herbicides, and stearates.

l Powder Coatings: Perfect for grinding epoxy, polyester, hybrid coatings, UV-curing acrylates, and polyamide.

l Food: Used to finely grind sugar, cacao, starch, fish meal, xanthan, guar flour, and lactose.

l Pharma/Cosmetics: Commonly used for making face powder, ascorbic acid, and tartaric acid.

l Minerals: Effective in processing talc, kaolin, calcium sulphate, bauxite, and limestone.

This machine’s versatility makes it a go-to solution for a wide range of material processing needs.

Parameter 1

| Motor(kw) | Rotated Speed(rpm) | ||||

Main Unit | Classifier | Feeder | Main Unit | Classifier | Feeder | |

CLQM-15 | 7.5 | 0.75 | 0.55 | 7000 | 800-3000 | 20-100 |

CLQM-20 | 11 | 1.1 | 0.55 | 5500 | 750-3100 | 20-100 |

CLQM-30 | 22 | 4 | 0.55 | 4000 | 700-2800 | 20-100 |

CLQM-45 | 30 | 5.5 | 0.55 | 3500 | 650-2600 | 20-100 |

CLQM-60 | 45 | 7.5 | 0.55 | 3000 | 600-2400 | 20-100 |

CLQM-100 | 55-75 | 11 | 1.1 | 2000 | 500-2000 | 20-100 |

CLQM-125 | 90-110 | 15 | 1.1 | 1600 | 400-1600 | 20-100 |

Parameter 2

Model | Diameter of rotor disc (mm) | Diameter of gear ring (mm) | Diameter of classifier (mm) | Linear speed of the outermost end of the rotor disc (m/s) | Air volume (m³/h)(max) | Product fineness (μm) | Output (kg/h) | Main Unit Dimension (L*W*H mm) |

CLQM-15 | 300 | 366 | 175 | 110 | 700-1200 | 3-300 | 10-200 | 1450*900*1000 |

CLQM-20 | 300 | 366 | 175 | 87 | 1300-2800 | 5-300 | 20-600 | 1450*900*1000 |

CLQM-30 | 400 | 470 | 242 | 84 | 2200-3600 | 5-300 | 30-1000 | 1740*1190*1100 |

CLQM-45 | 550 | 601 | 274 | 102 | 3600-6500 | 10-300 | 40-1200 | 1940*1250*1170 |

CLQM-60 | 700 | 774 | 350 | 110 | 4000-7500 | 10-300 | 50-1500 | 2150*1460*1380 |

CLQM-100 | 1000 | 1080 | 414 | 106 | 8000-12000 | 10-300 | 80-3000 | 2840*2150*1760 |

CLQM-125 | 2000 | 1295 | 461 | 101 | 12000-16000 | 10-300 | 120-5000 | 3000*2380*2000 |