For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

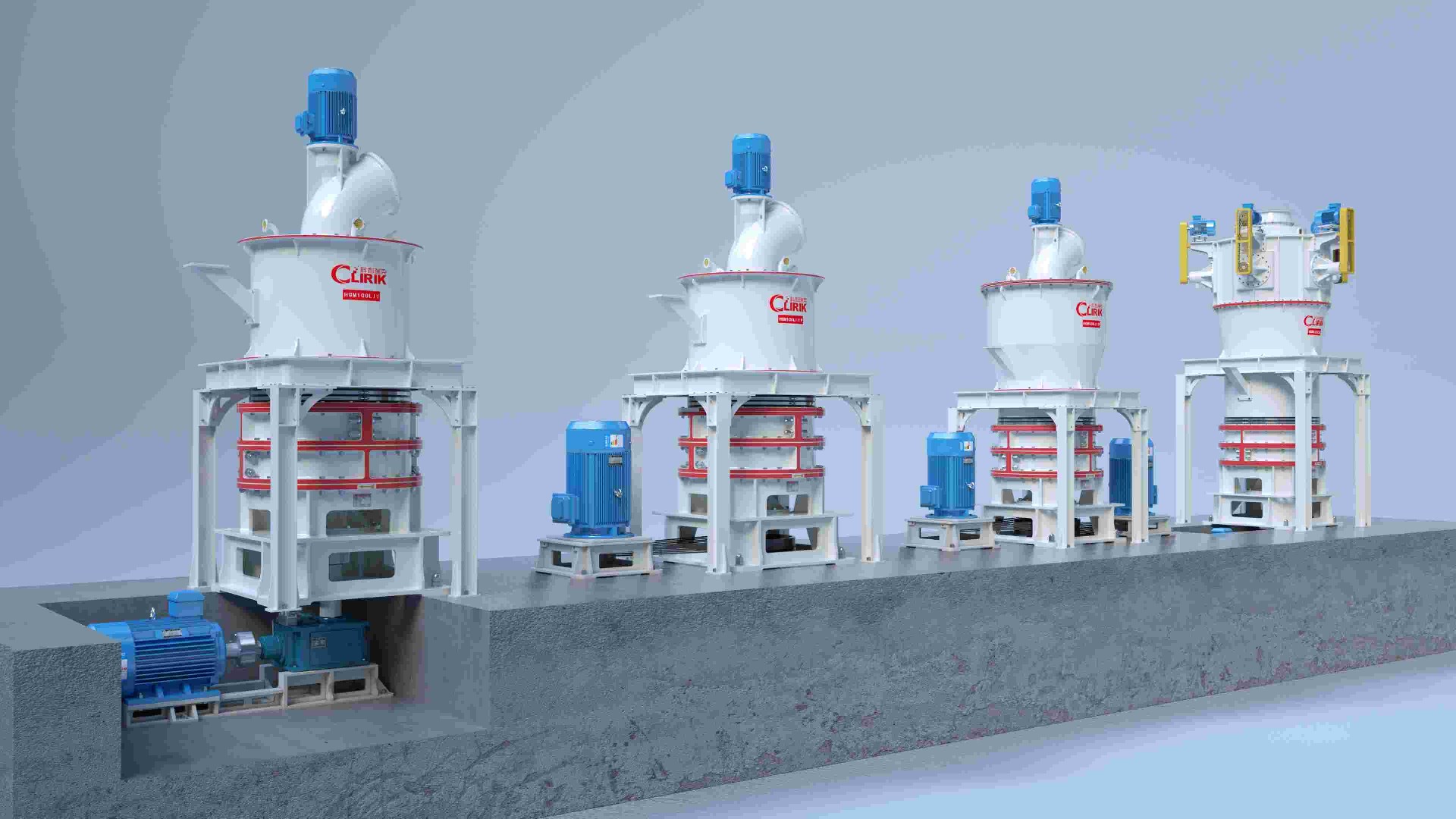

The HGM125 Ultrafine Grinding Mill is a high-capacity grinding solution designed for producing fine powders.

It features 32 rollers arranged in four layers, with the upper two layers consisting of 7 rollers each and the lower two layers having 9 rollers each. This configuration enhances the grinding efficiency and ensures a uniform particle size distribution.

The power configuration of the HGM125 includes a main unit with 185 kW, a classifier with 75 kW, and a blower with 132 kW. This powerful setup enables the mill to handle large volumes of material efficiently.

The HGM125 is capable of producing significant quantities of fine powder. At a 200-mesh output, it can produce up to 12 tons per hour, while at a 1000-mesh output, the production rate is 6 tons per hour.

Under standard operation, the daily output can reach up to 100 tons per day, and with 24-hour continuous operation, this figure can be increased to 200 tons per day.

The HGM125 Ultrafine Grinding Mill is extensively used in various countries, including Bangladesh, Korea, and Ethiopia, for high-volume mineral processing. It is preferred by large-scale industrial clients for its unmatched throughput and efficiency.

l Ring Diameter: 800 mm

l Roller Number: 18-21

l Main Shaft Speed: 230-240 r.p.m.

l Input Size: ≤10 mm

l Finished Size: 74-5 µm (200-2500 mesh)

l Capacity: 0.4-4.5 tons per hour

l Features: Suitable for laboratory and small-scale production, with high precision, energy efficiency, and environmental compliance.

l Ring Diameter: 900 mm

l Roller Number: 24-29

l Main Shaft Speed: 200-220 r.p.m.

l Input Size: ≤10 mm

l Finished Size: 74-5 µm (200-2500 mesh)

l Capacity: 0.6-6.5 tons per hour

l Features: Ideal for medium-scale production, capable of processing a variety of non-metallic minerals such as calcite, limestone, and dolomite.

l Ring Diameter: 1000 mm

l Roller Number: 28-36

l Main Shaft Speed: 180-200 r.p.m.

l Input Size: ≤15 mm

l Finished Size: 74-5 µm (200-2500 mesh)

l Capacity: 1-9 tons per hour

l Features: Suitable for medium to large-scale operations, known for its long-lasting components, reducing maintenance costs and downtime.

l Ring Diameter: 1680 mm

l Roller Number: 30-40

l Main Shaft Speed: 120-130 r.p.m.

l Input Size: ≤20 mm

l Finished Size: 100-9 µm (150-1500 mesh)

l Capacity: 3.8-30 tons per hour

l Features: The largest model in the series, designed for high-capacity production, ideal for large-scale industrial applications.

High Efficiency: Under the same finished size and motor power, the capacity of HGM mills is twice as much as jet mills, mixing grinders, and ball mills, with a 30% reduction in energy consumption.

Long Lifecycle of Spare Parts: The ring and roller are forged from special materials, ensuring a long service life, up to 2-5 years for grinding calcite carbonate.

High Safety and Reliability: No rolling bearings or screws in the grinding cavity, eliminating problems caused by bolt shedding or rapid wear of bearings and seal components.

High Fineness, Flexible Adjustment: The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 µm), with product fineness reaching D97≤5 µm.

Environmentally Friendly: The application of pulse bag filters and mufflers greatly reduces dust pollution and noise.

Shanghai CLIRIK Machinery Co., Ltd. is a leading manufacturer of grinding mill technology. Since its establishment, CLIRIK has adhered to the service philosophy of "All is for clients," providing high-quality, high-taste, high-efficiency, and all-around services. CLIRIK's HGM series mills are renowned for their innovative design, robust construction, and high-output performance, making them a top choice for industrial mineral grinding worldwide