For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

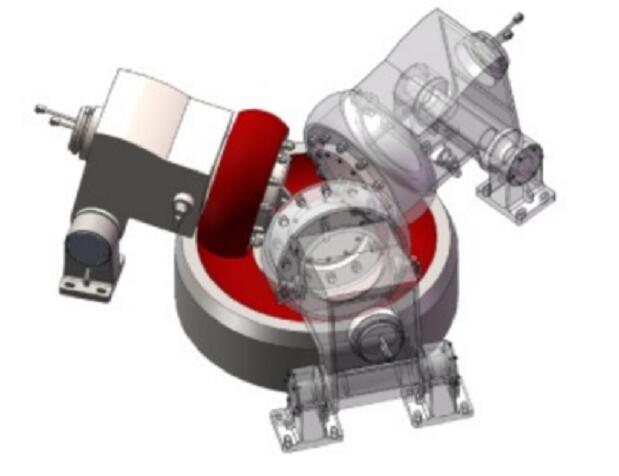

The CLUM Series Ultrafine Vertical Grinding Mill is designed with advanced technology and materials, offering outstanding performance in producing ultrafine powders with superior precision, energy efficiency, and environmental sustainability. It is equipped with a PLC frequency control system, special alloy wear-resistant materials, and a multi-head classification structure that ensures excellent grinding efficiency and product quality.

CLUM Series Ultrafine Vertical Roller Mill

The CLUM series mill offers precise control of particle size with an output fineness range from D97 5-45µm. Its high-efficiency PLC frequency control system allows for fine-tuning of grinding parameters. The mill can produce up to 2µm powders with a content range of 20%-70%, making it ideal for high-value powder applications across various industries.

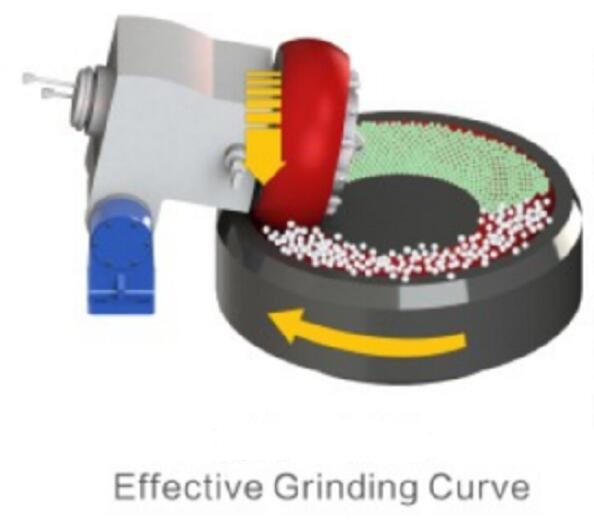

The mill's grinding rollers and grinding plates are made from special alloy wear-resistant materials, giving them a significantly longer service life compared to traditional materials. This results in a 40% reduction in energy consumption under similar working conditions.

The mill features a unique design where the grinding rollers have a convex surface and the grinding plate has a concave surface, forming an efficient material bed that increases the production capacity by 20%. Additionally, the multi-head classification system produces powders with narrow particle size distribution and uniform morphology, revolutionizing ultrafine powder production.

The CLUM mill is equipped with an advanced PLC/DCS automatic control system, ensuring precise control of grinding pressure. The system’s electronic and mechanical limit protections reduce vibrations and impacts, extending the equipment's lifespan and enhancing operational safety. This fully automated control system minimizes manual intervention and boosts overall operational efficiency.

The mill’s gearbox and lubrication system feature multiple monitoring and protection devices. An independent lubrication station ensures continuous operation with dual-pump lubrication for each grinding roller, preventing oil accumulation in the bearing chambers and guaranteeing smooth, efficient, and stable operation.

The lubrication system's cooling function ensures consistent performance, preventing overheating and reducing the risk of equipment failure. This design guarantees safe and continuous operation.

The CLUM series mill features a sealed, negative pressure production system that reduces dust emissions. The integrated air conveyance system transports the finished products directly into large storage silos, maintaining a clean, dust-free production environment. This system adheres to modern, environmentally-friendly manufacturing standards.

The CLUM series mill is ideal for a wide range of industries where ultrafine powders are required, including:

1. Non-Metallic Minerals:

Suitable for grinding minerals such as barite, calcite, limestone, dolomite, quartz, and talc, which are used in industries like coatings, rubber, plastics, and paper.

2. Chemical Industry:

It is used for producing high-value chemical products, such as catalysts, pigments, and fillers, with precise particle size control.

3. Paints and Coatings:

The mill produces fine powders with narrow particle size distributions and uniform shapes, making it ideal for high-quality paints and coatings, improving coverage, color stability, and application performance.

4. Construction Materials:

It can grind minerals used in producing construction materials, cement additives, and sealants, improving strength, stability, and corrosion resistance.

5. Plastics and Rubber:

The mill is used to produce fine fillers for plastics and rubber, enhancing durability, hardness, and impact resistance of the products.

6. Paper Industry:

Fine minerals ground by the CLUM mill can be used as fillers and coatings in paper manufacturing, improving smoothness, whiteness, and printability.

7. Pharmaceuticals and Food Processing:

The mill is ideal for producing fine powders for pharmaceuticals and food additives, such as calcium carbonate, talc, and other high-purity ingredients.

8. New Energy Materials:

The mill is used in producing fine powders for energy materials like lithium battery components and photovoltaic materials, enhancing battery performance and energy density.

Feature | CLUM Series Ultrafine Vertical Mill | Raymond Mill / Ball Mill / Ring Roller Mill |

Fineness Control | Precise control with output fineness from D97 5-45µm and flexibility to adjust 2µm content from 20%-70%. | Typically struggles to produce stable ultrafine powders with narrow particle size distribution. |

Production Capacity | High efficiency, increased by 20%-30% compared to traditional mills due to unique alloy materials and grinding structure. | Lower production efficiency, especially for ultrafine powder, with frequent maintenance. |

Durability and Service Life | Made with special alloy materials that significantly reduce wear and tear, extending service life by 40% compared to traditional materials. | Frequent wear and higher maintenance costs due to less durable materials. |

Automation and Control | Advanced PLC/DCS control system with electronic and mechanical limit protections, reducing manual intervention and ensuring precise operation. | Lower automation level, requiring more manual operation and monitoring, resulting in lower precision. |

Environmental Protection | Sealed negative pressure design and dust-free operation ensure a clean and environmentally friendly production environment. | Typically lacks effective dust control, leading to environmental concerns and higher maintenance. |

Running Costs | Lower energy consumption and reduced maintenance costs due to durable materials and automated controls. | Higher operational costs due to energy inefficiency, frequent maintenance, and manual operation. |

Material Adaptability | Suitable for a wide range of materials, including non-metallic minerals, chemicals, plastics, and more. | Less adaptable to different materials, particularly ultrafine powders. |

The CLUM Series Ultrafine Vertical Grinding Mill stands out in terms of performance, efficiency, durability, and environmental sustainability. Compared to traditional mills like Raymond mills, ball mills, and ring roller mills, the CLUM series excels in producing high-quality ultrafine powders with narrow particle size distributions. It is particularly suitable for industries requiring high-value products and efficient, eco-friendly production processes.