For product information and pricing, Chat with sales agent:

or email us : sales@clirik.com

Click links below to see related products.

Eggshells are often overlooked as waste, yet they possess significant potential as a valuable resource due to their high calcium carbonate content.

With growing environmental concerns and the demand for sustainable practices, the recycling and grinding of eggshells have emerged as promising avenues for both reducing waste and creating valuable by-products.

This article explores the significance of eggshell recycling, the grinding process, and the types of grinding equipment used in producing eggshell powder of varying fineness levels.

Eggshell recycling is essential for several reasons:

l Resource Utilization: Eggshells are rich in calcium carbonate, which can be processed into various products like calcium supplements, fertilizers, and industrial fillers. Utilizing eggshells effectively reduces resource waste and enhances economic value.

l Environmental Protection: Recycling eggshells helps reduce landfill waste and lowers environmental pollution, particularly by decreasing the release of carbon dioxide during decomposition.

l Economic Benefits: By converting waste eggshells into marketable products, industries can generate additional revenue, thereby making eggshell recycling a profitable endeavor.

The applications of eggshell powder vary depending on the fineness of the grind:

l Feed Additive: Used in poultry feed to provide calcium, improving eggshell quality and bone strength in birds.

l Organic Fertilizer: Applied directly as a soil amendment to improve soil structure and increase calcium content.

l Soil Conditioner: Used to regulate soil pH, particularly in acidic soils.

l Building Material Filler: Incorporated into materials like cement and paint to enhance strength and durability.

l Food Additive: Added to food products as a dietary calcium supplement.

l Pharmaceutical Additive: Used in the production of calcium tablets and other supplements.

l Personal Care Products: Included in toothpaste and skincare products as a natural mineral component.

l Biomedical Materials: Utilized in bioceramics and bone fillers for medical applications.

l Nanomaterials: Processed into nanocoatings and nanocomposites for industrial use.

l 3D Printing Materials: Employed as a filler in bio-based 3D printing materials.

The process of grinding eggshells into powder involves several steps:

1. Cleaning and Disinfection: Eggshells are cleaned to remove any remaining egg white and disinfected to ensure safety.

2. Drying: The cleaned shells are dried using drying equipment to prevent mold and prepare them for grinding.

3. Grinding: The dried eggshells are ground into powder using specialized equipment. The choice of grinding machine depends on the desired fineness of the final product.

4. Screening: The ground powder is screened to ensure that it meets the required fineness standards.

5. Packaging: The final product is packaged and stored in a controlled environment to maintain its quality.

Different types of grinding equipment are used to produce eggshell powder of varying fineness levels:

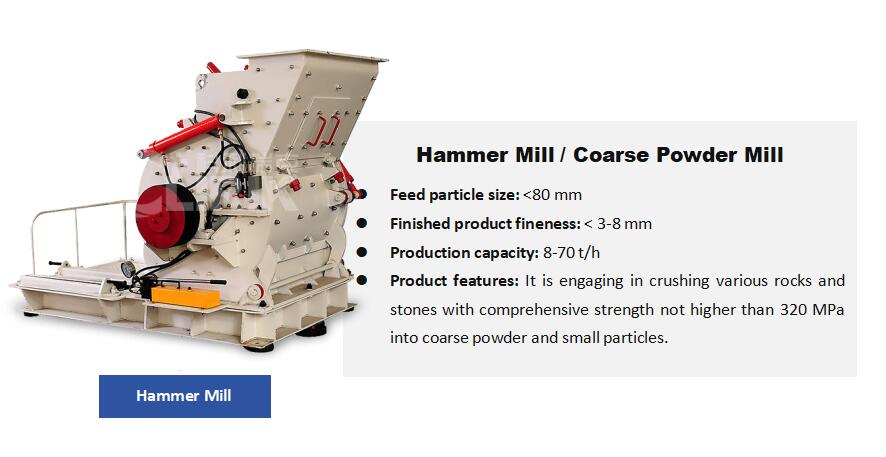

l Hammer Mill: Used for initial crushing, reducing eggshells to coarse particles.

l Raymond Mill: Further grinds the particles into coarse powder suitable for agricultural applications.

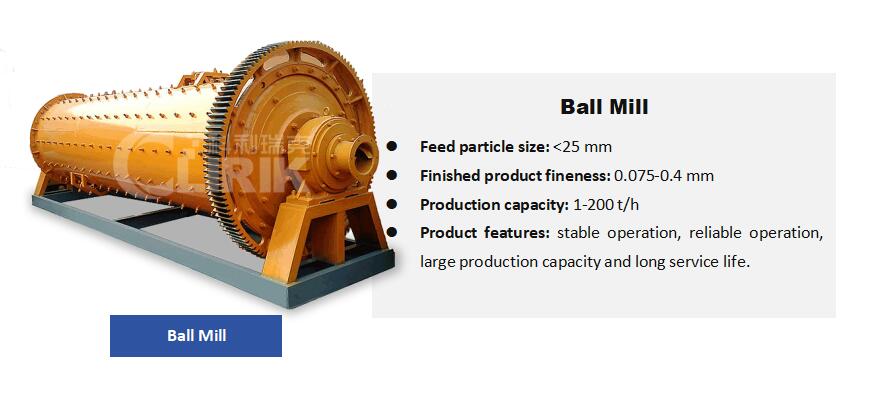

l Ball Mill: Suitable for grinding eggshells into medium-fine powder for industrial use.

l Raymond Mill: Also effective for producing medium-fine powders for use in building materials.

l HGM Ultrafine Grinding Mill: Ideal for producing fine powder used in food and pharmaceutical applications, ensuring a uniform and high-quality product.

l High-Pressure Micro Powder Mill: Capable of producing fine powders, particularly useful in creating food-grade calcium supplements.

l HGM Ultrafine Grinding Mill: Also used for producing ultrafine powder for high-end applications like biomedical materials and nanotechnology.

HGM Ultrafine Grinding Mill for Eggshells Powder Making

Investing in eggshell powder processing can be highly profitable due to the growing demand across various sectors:

l Market Demand: The demand for calcium supplements in the food and healthcare industries is rising, driven by health-conscious consumers. Additionally, the agricultural and construction sectors require eggshell powder as soil conditioners and fillers, respectively. Emerging fields like biomedicine and nanotechnology also present significant opportunities for ultrafine powder.

l Profit Margins: The cost of raw eggshells is low, while the added value of the processed powder varies based on fineness and application. Fine and ultrafine powders, especially those used in high-end applications, command higher prices and offer greater profit margins.

l Market Competition: Companies equipped with advanced grinding technology have a competitive edge in producing high-quality, ultrafine eggshell powder, particularly for specialized applications.

The recycling and grinding of eggshells present a unique opportunity to convert waste into valuable products. By utilizing the appropriate grinding equipment, businesses can produce eggshell powder of varying fineness levels, catering to diverse market needs. As demand for sustainable and innovative products grows, the market for eggshell powder is poised to expand, making it a promising area for investment and development.