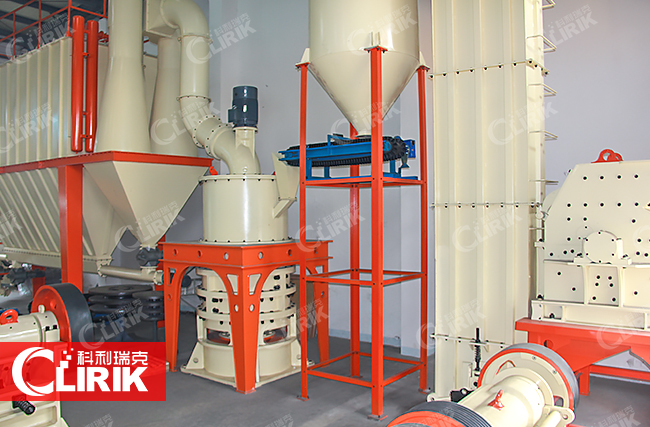

First of all, the material affects the service life of the grinding roller and the grinding ring of the

grinding mill. If the material has good wear resistance, the wear will be less and not easily damaged when the material is processed. If the material has poor wear resistance, it is prone to failure when producing materials, and the production efficiency is low, so the choice of materials has a very important influence on the processing.

Secondly, when choosing the material of the grinding roller grinding ring, we must first understand which kind of material is good. For the current selection of materials for the

grinding mill manufacturer, the general manufacturers choose high manganese steel and other resistant. The material with higher grinding performance, so the equipment processed by such manufacturers has better quality, the service life is relatively long, and the performance is better when the materials are processed.

Of course, the wear resistance of the material is even better. In the production process of the

grinding mill, the wear and tear is present, the service life of the equipment and internal parts is only relatively extended, and the service life is still limited. In order to reduce this phenomenon, in order to reduce In the production of operating costs, when using the machine, it is necessary to carry out reasonable maintenance and maintenance operations, as much as possible to reduce the wear on the grinding ring, to ensure smooth production.

The above describes in detail how to choose the material of the grinding roller ring of the

grinding mill.

Firstly, it analyzes the importance of the material for the production of the mill.

Then it introduces that the material such as high manganese steel is better on the market. Materials, and then analyze the importance of the maintenance of parts in production, reasonable maintenance is another important condition to extend the service life of equipment.